The VORTEX effect

"Discover the innovation of vortex tubes, a technology that uses compressed air to generate both cold and heat.

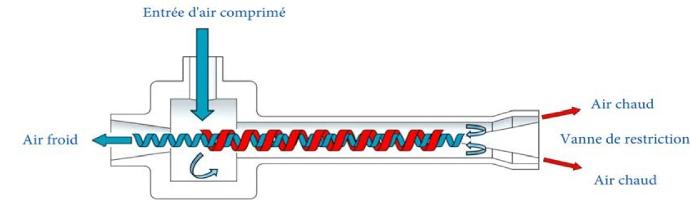

The compressed air injected through the inlet creates a high-speed swirling flow (1,000,000 rpm) inside the tube, known as the vortex effect. The air propelled at high speed heats up against the walls of the tube, reaching temperatures of up to 200°C.

At the end of the tube, a restriction valve limits the exhaust flow of hot air. The remaining air, unable to escape, is forced back and travels in the opposite direction within the hot air vortex. This slower airflow causes a significant heat exchange, cooling the air dramatically before it exits the tube from the opposite side, reaching temperatures as low as -45°C, with a thermal flow rate of up to 2,500 kcal/h.

Installation

To be effective, a vortex tube must be supplied with very dry, clean, and filtered compressed air at 5μ. The tube and the supply connection must not have any passage restrictions with diameters smaller than 8 mm.

The adjustment of the hot air outlet restriction valve allows for controlling the flow rate and the cooling level of the cold outlet.

The higher the cold outlet flow rate, the smaller the temperature drop, and the greater the production of frigorifics (fg)

Conversely, the lower the cold outlet flow rate, the greater the temperature drop, and the lower the production of frigorifics (fg).

ncreasing the compressed air pressure increases the temperature drop at the cold outlet, while decreasing the pressure reduces it.

The presence of moisture in the supply air causes condensation and the formation of frost, which hinders the operation of the tube.

Refrigeration capacity

Refrigeration capacity :

Refrigeration unit

It refers to the amount of heat required to lower the temperature of 1 gram of water by 1°C, from 14.5°C to 15.5°C, under normal atmospheric pressure.

Expressed in kilocalories (Kfg).

Its unit of measurement is the inverse of the calorie.

Its value is -4.185 Joules..

Its unit of measurement is named after the Latin word frigus (cold).

Why choose VORTEX tubes?

Ease of use

No special skills required for installation.

Eco-friendly

No CFC gas emissions.

Maintenance-free

No moving parts.

Compact

High efficiency.

For which applications?

Precise cabinet air conditioning

Tire grinding

Plastic bottle cooling

Substrate cooling

Sonotrode cooling

Cooling of hot machine parts

Needle cooling

Part cooling

Complementary products

Compressed air filter

The Expel compressed air filter protects your equipment by eliminating 99.999% of water, oil emulsions...

Filter Regulator Lubricator

Protect your equipment and regulate pressure with our modular FRLs.