ISO 1, 2 & 3 solenoid-operated valves designed for glass industry applications

Precise and reliable airflow control for optimized performance

Solenoid-operated valves - ISO 1, 2 & 3

For IS machines

Discover the new generation of ISO 1, 2 & 3 pneumatic solenoid-operated valves for IS machines, designed for the glass industry.

The features are as follows:

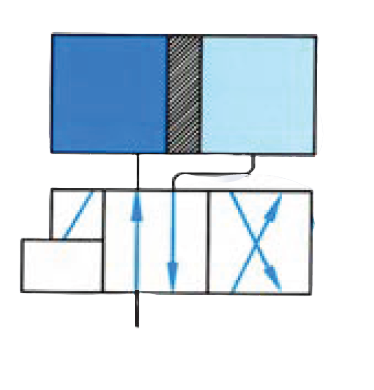

- ISO 5599/1 and 5599/2 standard.

- ISO mounting footprint (direct replacement installation).

- High resistance to contaminants – unaffected by pressure fluctuations.

- Designed to operate in the harshest environments.

- Fast and precise switching with extremely high repeatability.

- High-temperature modification for resistance up to 80°C (176°F) for the valve and its pilot.

- Reduced machine downtime – increased productivity.

- High performance – maximizes your machine’s efficiency throughout its operation.

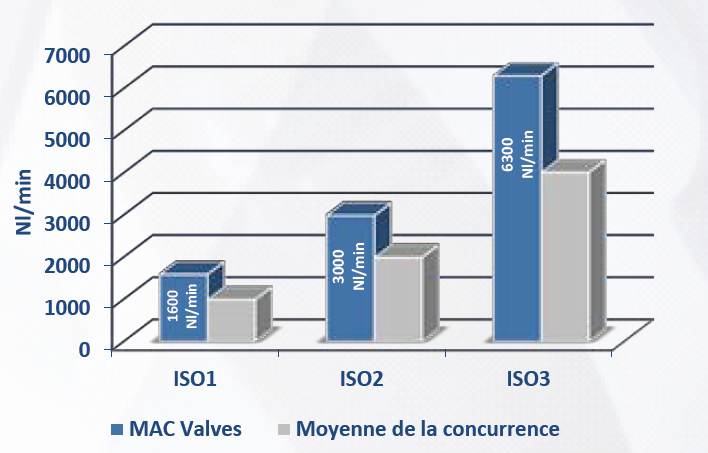

- Among the highest flow rates for standardized ISO solenoid-operated valves:

Why choose our solutions for your glassmaking applications?

SPEED

PRECISION

RELIABILITY

PERFORMANCE

Customer benefits:

Technical specifications:

Model | ISO 1 ISO 2 ISO 3 |

Fluid | Compressed air, vacuum, inert gases |

Main supply pressure: | External pilot: 0 to 8 bar |

Pilot pressure: | 2,5 to 8 bar |

Lubrication | Not required – if lubrication is used, apply a lubricant with a median aniline point (between 80°C and 100°C). |

Filtration | 40 μ |

Temperature: | -18°C to + 80°C |

Orifice diameter: | 7,8 mm / 0.27 in 10,5 mm / 0.39 in 14,9 mm / 0.55 in |

Flow rate (at 6 bar, ΔP = 1 bar): | 1600 Nl/min - Cv 1.6 3000 Nl/min - Cv 3.0 6300 Nl/min - Cv 6.3 |

Solenoid: | Epoxy-coated – Class F wire – long-duty excitation |

Supply voltage: | -15% to +10% of nominal voltage |

Mod. GL01 : | Viton seals, spool, and poppet – high-temperature grease – manual control designed for the glass industry. |

MAC solutions - ordering codes:

Model | ISO 1 | ISO 2 | ISO 3 |

Electric control version | MV-B1A-AAAx-DM-DEWJ-1xx / GL01 | MV-B2A-AAAx-DM-DEWJ- 1xx/ GL01 | MV-B3A-AAAx-DM-DEWJ-1xx / GL01 |

Repair kit (electric version): | DM-DEWJ-1xx / GL01 K-P1001 / GL01 | DM-DEWJ-1xx / GL01 K-P2001 / 446K | DM-DEWJ-1xx / GL01 K-P3001 / 446K |

Pneumatic control version: | Not available | MV-R2A-BACF / 446D | MV-R3A-BACF / 446D |

Repair kit (pneumatic version): | - | K-P2001 / 446K | K-P3001 / 446K |

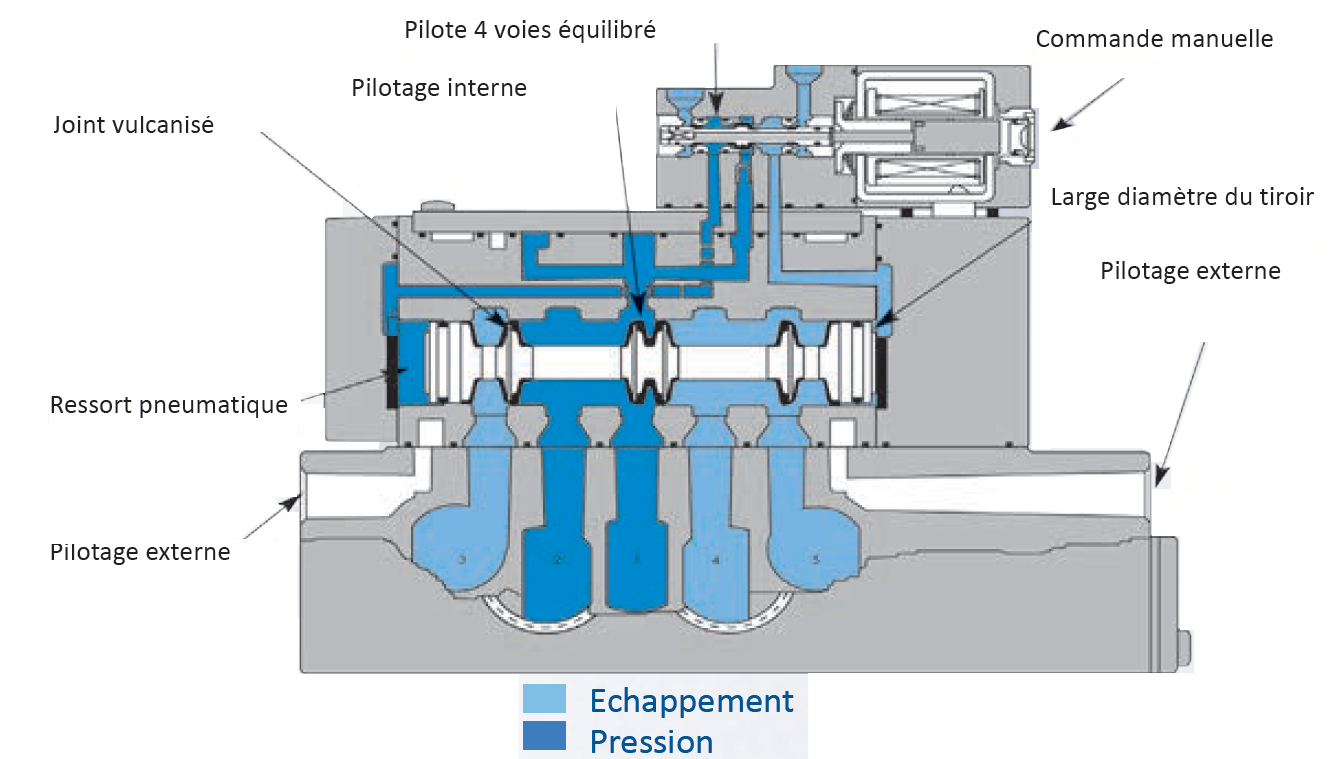

Benefits of the MV-XXA series:

Benefits :

- High translation forces in both directions.

- No resistance opposes the translation forces.

- The full spool cross-section is utilized.

Explore our other solutions for glassmaking:

Our components