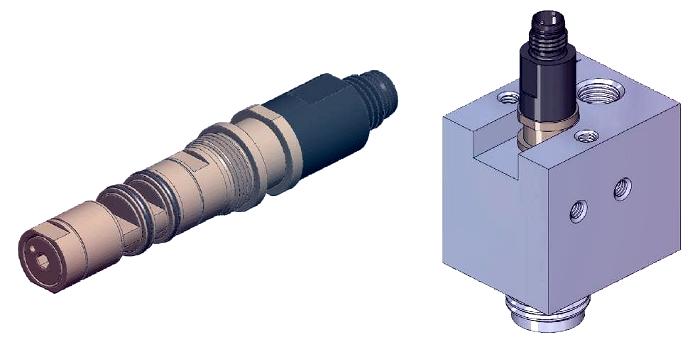

All-fluid cartridge solenoid valves for the food industry

Water jet scarification

Scoring the dough is an essential process in the baking industry. To achieve a consistent incision in both depth and length, it is crucial to choose high-quality solutions.

This is where the MAC Valves double diaphragm liquid solenoid valves come into play. These solenoid valves offer exceptional performance and unmatched reliability for the water jet scarification process.

Development of solutions in place

When it comes to scoring the dough, the development of tailored solutions is crucial.

The MAC Valves all-fluid double diaphragm cartridge solenoid valves use cutting-edge technology to meet the specific requirements of this process.

Their balanced design allows for a consistent incision in both depth and length, ensuring the quality of the final product.

Biocompatible greases and materials

In the food industry, it is essential to use safe and hygienic components.

The all-fluid cartridge solenoid valves are made from biocompatible materials, ensuring optimal compatibility with food industry requirements.

In addition, the stainless steel solenoid valve bodies provide exceptional resistance to corrosion and wear, thereby extending the lifespan of the valves.

IP95 protection

Food production environments can be demanding, with conditions such as humidity and dust.

The MAC Valves all-fluid double diaphragm cartridge solenoid valves are equipped with IP65 protection, dustproof and waterproof.

This ensures reliable operation even in challenging conditions.

Operating pressure

The MAC Valves all-fluid double diaphragm cartridge solenoid valves can operate at pressures up to 14 bar, providing great flexibility to meet the specific needs of each application.

This high pressure capacity ensures consistent and precise performance during the water jet scarification process.