Solutions to flow problems

The AirSweep system

Flow problems can lead to a 'snowball' effect in material silos, disrupting the entire process and requiring manual cleaning. To avoid these inconveniences, it is crucial to implement reliable solutions such as deblinding, the use of air cannons, vibrators, and other suitable devices.

Before worrying about the cost associated with installing these flow aid devices, it is important to consider the potential cost of their absence. By investing in effective solutions from the start, you avoid compensatory delays and disruptions in your workflow.

Maintaining optimal flow in your tanks, hoppers, and silos is essential to ensure optimal productivity and minimize flow-related issues.

The consequences of flow problems

Productivity loss: A major industrial company in Southeast Asia assessed its losses at $12,000 per hour due to frequent downtime caused by flow problems. These unplanned shutdowns resulted in significant financial losses, wasted valuable labor hours, and put the company's workers at risk.

Money loss: Companies invest significant amounts in acquiring high-performance materials to address their flow problems. However, due to material buildup in certain tanks, some companies have been forced to waste the mixtures produced during their production process.

Worker safety risks: To facilitate the flow of materials in tanks and silos, it is crucial to avoid dangerous practices such as banging on tanks or climbing silos. These unsafe methods can lead to serious physical injuries, severe respiratory issues, and even fire risks due to volatile gases released by trapped materials.

Choose the right solution for your material flows

Speed and efficiency: The AirSweep pneumatic flow aid system reduces the time to fill supersacks from one hour to 2 minutes. AirSweep provides an efficient solution to solve your flow problems. With this advanced technology, your process will be further improved.

Operating costs: Do not limit yourself to considering only the purchase price when choosing a flow aid system. Take into account all the costs associated with its use, such as energy consumption, cleaning and maintenance requirements, as well as the potential impact on your tank.

Productivity and optimization: The AirSweep system is designed to help you further increase your productivity and optimize your time. With this innovative solution, you can effectively solve flow problems, eliminate blockages, and maximize the efficiency of your process.

AirSweep, the most effective solution for your flow problems.

AirSweep is the ideal solution to eliminate:

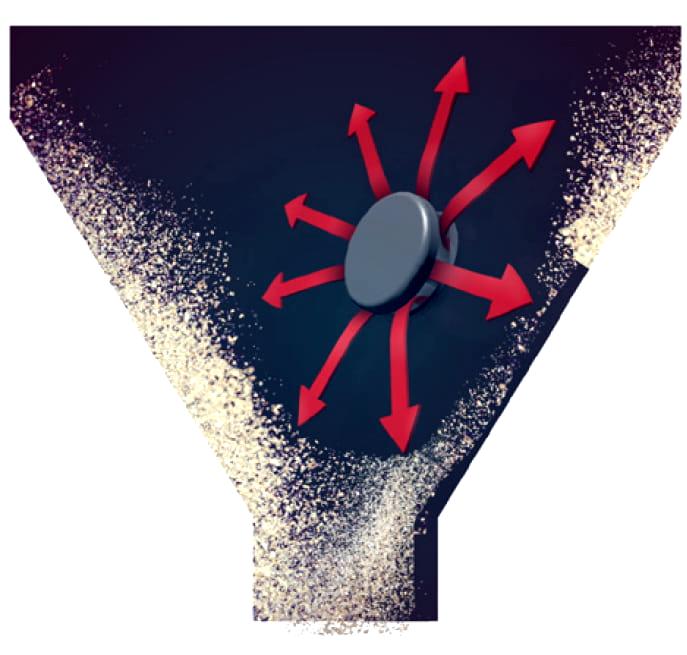

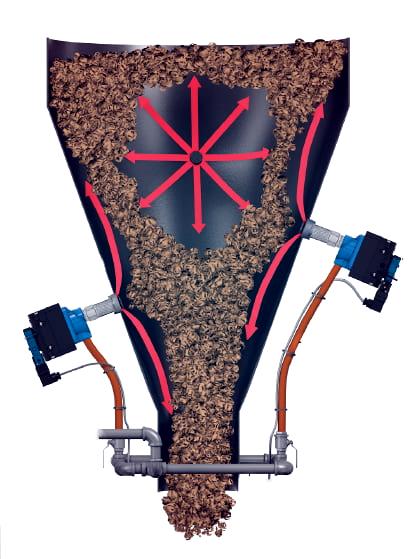

Bridging

Air pockets

Material buildup

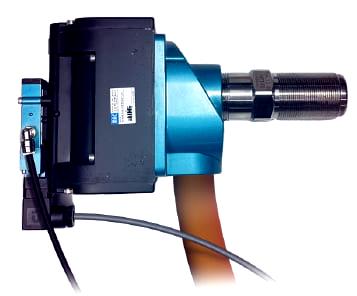

Thus ensuring flow optimization. This innovative system consists of nozzles mounted on the outside of the tank and connected to a solenoid valve.

Each nozzle releases high-pressure, high-volume compressed air, allowing blocked materials to be dislodged and reintegrated into the flow.

The nozzles can be programmed to open in a specific sequence, making them more effective for the flow of certain materials.

The savings achieved with the AirSweep system

Increase in productivity

Reduce cleaning time between two product runs.

Product quality

Improve product uniformity

No material return.

The nozzle closes after each pulse, eliminating any material backflow. This means less damage, less cleaning, and no risk of contamination.

No noise disturbance

AirSweep operates with a slight whistle.

Low maintenance and energy costs

Avoid wear on the tank walls and use less than 0.28 cubic meters of air.

Safety

Workers no longer have to climb tanks or lift heavy materials.