Double ring fittings - stainless steel

Discover our range of double ring stainless steel fittings, designed for optimal performance.

In applications where conditions are harsh and pressure is high, it is recommended to consider the following installation procedures:

- Ensure that the nut is hand-tightened.

- Insert the tube.

- Tighten the nut with a wrench until the tube no longer rotates freely.

- Mark the position of the nut.

- Turn the nut 1 and 1/4 turns by hand.

This method ensures that even if the tube O.D. is at the minimum tolerance, the fittings will remain in contact with the tube throughout the 1 and 1/4 turn hand-tightening process.

Specifications :

Type of fluid | Air (no type of gas or liquid) |

Operating pressure | -20 - +140°C |

Temperature range | ** |

Sealing (gaskets) | FKM |

*Depends on the operating temperature range of the tube used. For more information, please contact us.

**Depends on the maximum pressure range of the tube used. For more information, please contact us.

Tube handling :

Tube sélection :

It is important to handle the tube carefully in order to significantly reduce the risk of leaks due to potential scratches on the tube. If you are using copper tubing in coils, hold the end of the tube and roll the coil outward so that the tube rests on a flat surface.

Utilisation

Do not place the tubes on the floor.

Tubes should not be pulled out of a tube rack, especially in the case of large diameter tubes.

In order to ensure maximum reliability and performance of the fittings, particular care should be taken in selecting the tubes for each application. Four variables must be considered when ordering tubes intended for use with fittings:

- The material

- The wall thickness of the tube

- Surface finish of the tube

- Tube hardness

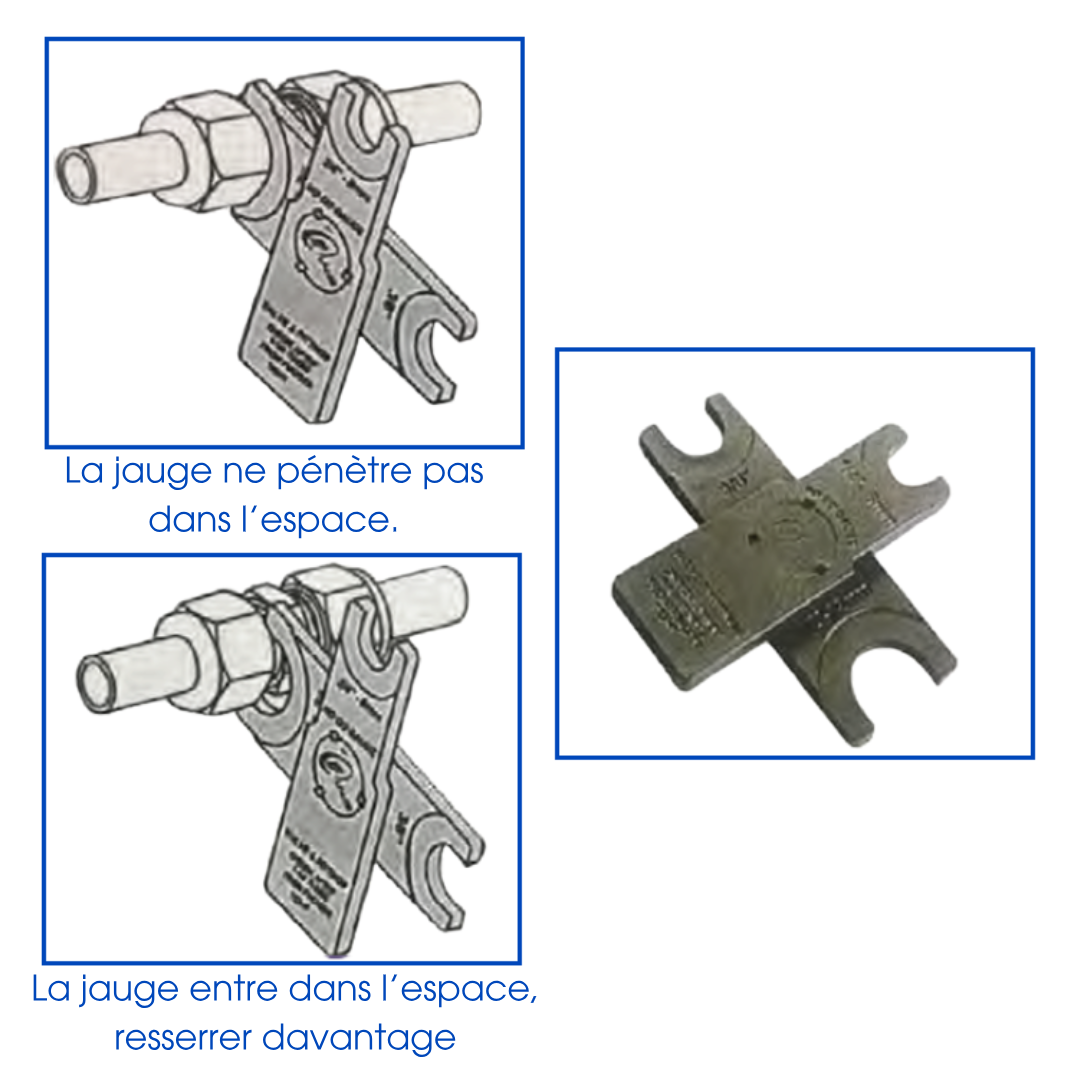

Inspection gauge:

This is a 'no-depth' gauge that should be used as:

Utilisation

- Perform the assembly according to the following instructions: 1/4 inch (6mm), 1/2 inch (12mm)

- Tighten 1 and 1/4 turns by hand.

- Check the gap between the nut and the body using the appropriate depth gauge.

- If the gauge slides easily into the gap, tighten the nut further until the gauge cannot enter the gap.